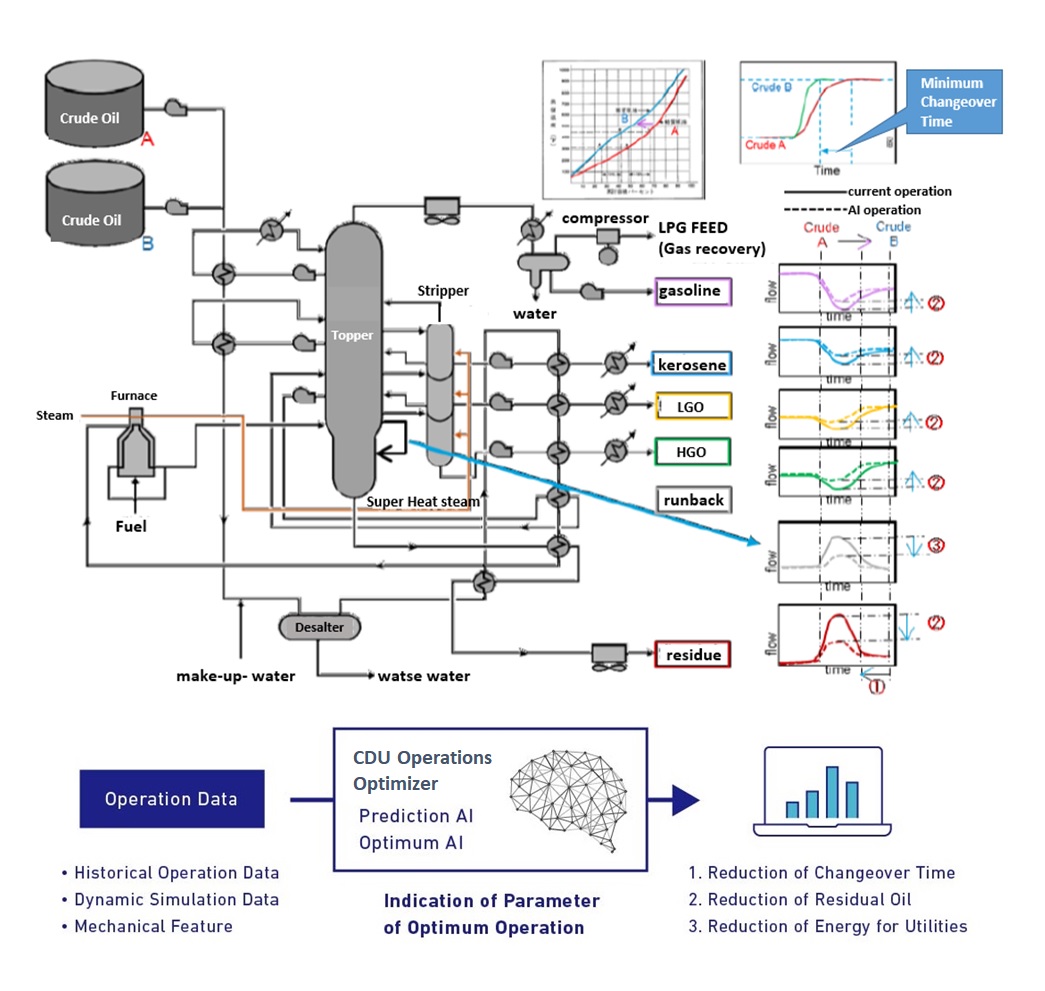

Japanese Domestic refineries are doing refining business by using various types of crude oil as raw materials. The switching of crude oil types occurs at a frequency of once every few days, and the oil type switching operation of the crude oil distillation column is carried out each time.

In order to prioritize product quality while crude oil and product properties fluctuate in the oil type switching operation, the yield of kerosene, gas oil, etc. from the crude oil distillation column is reduced and product loss occurs.

In addition, it is necessary to operate while considering the wide range of effects such as energy saving, product loss minimization, operation restrictions such as corrosion, and early switching operation while the flow rate balance is avoided. Because of the complexity of operation, a single control model is not adopted nor automation has not been reached.

Furthermore, due to the aging of the operator and the retirement of skilled operators, and the range of support for each operator is expanding, technology transfer has become a difficult problem.

It is expected that the CDU Operations Optimizer is to reduce the work load on operators, improve the yield of kerosene and gas oil, reduce utility costs in the oil type switching operation by the indication of the best parameters of the optimum operation by using AI technology. And the system contributes the transfer of skill and knowledge of skilled operators to junior operators.